The 2018 Edition of NFPA 70E is quickly approaching. Here is a link to an article by Jim Phillips / Brainfiller.com that was recently published in the May Edition of Electrical Contractor Magazine. As usual, some changes were minor, others were quite major. There is also quite a bit of reorganization.

2018 NFPA 70E Changes Article

PS: There are changes to the definition of arc flash boundary in the upcoming NFPA 70E Standard for Electrical Safety in the Workplace. Specifically, the revised definition of arc flash boundary no longer uses the term "second degree burn" but instead "at which incident energy equals 1.2 cal/cm2.", and the revised informational note references the Stoll skin burn injury model.

NFPA 70E year 2004 assumed that the incident energy requirement increases below one second. A quote from NFPA 70E year 2004 "For situations where fault-clearing time is 0.1 second (or faster), the Flash Protection Boundary is the distance at which the incident energy level equals 6.24 J/cm^2 (1.5 cal/cm^2)." This reference was removed in NFPA 70E year 2012 edition. NFPA 70E year 2012 stated that "a second degree burn is possible by an exposure of unprotected skin to an electric arc flash above the incident energy level of 1.2 cal/cm2 ( 5.0 J/cm2 )" and assumed 1.2 cal/cm2 as a threshold incident energy level for a second degree burn for systems 50 Volts and greater. NFPA 70E year 2015 explicitly prohibited using incident energy and PPE category together. The NFPA Handbook from 2015 showed a sample label with fields to be filled in for "available incident energy" and "level of PPE" while just half a page earlier states that "available incident energy" cannot be included with the "PPE category" in table 130.7(c)15(A)(b).

The revised definition of arc flash boundary in NFPA 70E year 2018 is even more misleading. It also contradicts the accompanying revised informational note referencing the Stoll skin burn injury model. A quote from A.Stoll "Heat Transfer in Biotechnology" summarizes the issue of using a critical thermal load approach in determining arc flash boundary. The quote reads:

"Serious misconceptions have crept into this field of research through adoption of rule-of-thumb terminology which has lost its identity as such and become accepted as fact. A glaring example of this process is the “critical thermal load.” This quantity is defined as the total energy delivered in any given exposure required to produce some given endpoint such as a blister. Mathematically it is the product of the flux and exposure time for a shaped pulse. Implicit in this treatment is the assumption that thermal injury is a function of dosage as in ionizing radiation, so that the process obeys the "law of reciprocity," i.e., that equal injury is produced by equal doses. On the contrary, a very large amount of energy delivered over a greatly extended time produces no injury at all while the same "dose" delivered instantaneously may totally destroy the skin. Conversely, measurements of doses which produce the same damage over even a narrow range of intensities of radiation show that the "law of reciprocity" fails, for the doses are not equal."

Here is what ASTM F1959/F1959M Standard Test Method for Determining the Arc Rating of Materials for Clothing says about skin burn injury determination:

"12.1.4 Predicted Second-Degree Skin Burn Injury Determination (Stoll Curve Comparison) — The time dependent averaged heat energy response for each panel [..] is compared to the Stoll Curve empirical human predicted second-degree skin burn injury model:

Stoll Response, cal/cm2 = 1.1991 * ti^0.2901

where ti is the time value in seconds of the heat energy determination and elapsed time since the initiation of the arc exposure. A second-degree skin burn injury is predicted if either panel sensor heat energy response exceeds the Stoll Response value (at time ti)."

Incident energy alone has no impact on thermal damage and blast pressure. One can expose himself to any arbitrary incident energy and suffer no damage as long as the energy is delivered at slow enough rate. On the other hand, an exposure to only a fraction of 1.2 cal/cm2 may result in incurable burn provided that the energy has been delivered fast enough. Read Evaluation of onset to second degree burn energy in arc flash hazard analysis for more information. The issue of using incident energy as a measure of damage alone and without regard to the rate of the energy release has been raised to NFPA 70E committee before year 2015 edition was published but unfortunately it was never appropriately addressed by the group.

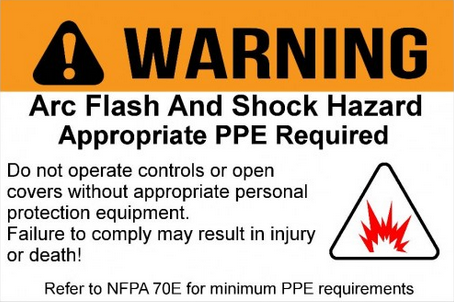

Figure 1A. An example of generic arc flash warning label.

Figure 1A. An example of generic arc flash warning label.